Solutions for smart factories with Industry 4.0 services

The Industrial Internet of Things (IIoT) connects intelligent devices, machines, and sensors via networks supporting continuous interoperability and communication to optimize and control smart production environments. Digitalization and interconnectivity have transformed the industrial landscape into fully integrated production systems capable of operating in real time manufacturing and logistic settings. Smart factories rely on components and machinery tested and certified to meet country-specific rules, alliance approvals and standardized regulations.

We conduct comprehensive services to test and certify intelligent machines and autonomous equipment while providing smart solutions for connected factories in all industrial sectors. Our experts conduct interoperability, performance and safety testing to ensure the electro mechanical compatibility, cyber security and functional safety of your smart factory. We help you fulfill all requirements relevant to your particular circumstance with services tailored to your business needs.

Our global network of experts is well-versed in recognized CE Directives as well as cTUVus Certification for the US and Canada. We provide reliable risk assessment and comprehensive robotics and automation testing of your devices and machinery. We certify industrial network cyber security according to IEC 62443 standards and test according to all wireless and radio protocols.

Smart Industry solutions for safe and secure connected factory equipment

Our Industry 4.0 services are designed to ensure the compliance, performance, and safety of your manufacturing equipment and systems. We make sure all devices for use in connected production networks meet recognized reliability, interoperability, security and safety standards. We conduct accredited services for diverse international approvals and certifications. We help you understand technical requirements and implement targeted solutions for smart manufacturing. Our one-stop-shop consists of a worldwide service network to provide you reliable and informative support for each and every project. We are able to serve you at anytime, anywhere in the world.

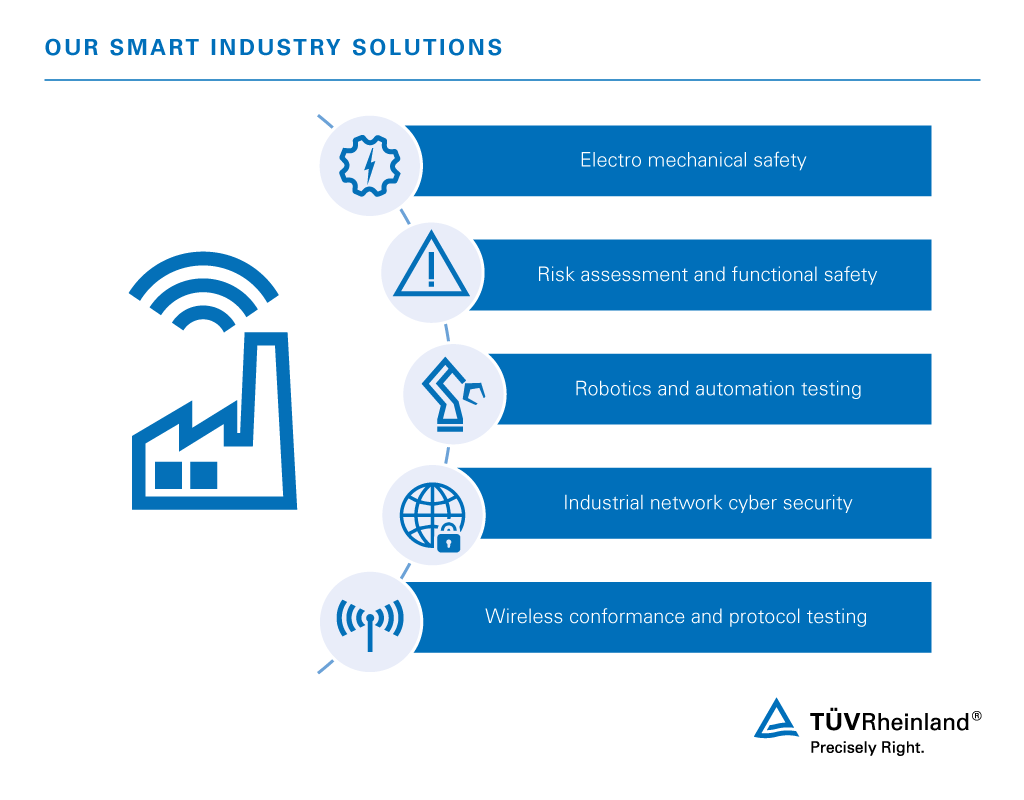

Our Smart Industry services

We provide comprehensive testing and certification services according to local codes and directives as well as global industrial standards to ensure your components, machinery, and systems are ready to successfully operate within the smart factory environment. We test and certify:

- Electro mechanical safety

CE Directives, cTUVus certification and field evaluation - Risk assessment and functional safety

- Robotics and automation

- Operational technology cyber security

IEC 62443 series of standards - Wireless regulatory and protocol conformance, performance and interoperability

- Safety conformity process for manufacturers, implementation support for integrators and operators

Smart factories built with intelligent machines, sensors and communications protocols that are connected via networks also rely on operational and maintenance personnel to keep the plant up and running. All components, machinery and systems must therefore be tested and certified according to recognized standards to ensure employee safety. We assist you in making sure:

- Automated machinery, robotics, and processes on the production floor, in the warehouse and throughout any commercial facility are able to properly react to unexpected human activity.

- Electro-mechanical systems including battery-powered mobile autonomous equipment and automated guided vehicles meet national codes and directives to prevent fire, electrical shock and physical harm.

- System and network security has been evaluated to assess the risk of potential breaches that could alter machine performance and process functions or create safety hazards and costly production shutdowns.

- Communication between your IIoT devices and systems meets wireless radio and protocol standards to ensure interoperability needed to support the steady data flow of information upon which factory employees and administrative personnel depend.

Our global network of experts is happy to serve you with comprehensive services according to your individual needs at anytime and anywhere from a single source.

Your Smart Industry 4.0 service provider

Our services have been developed to provide you the expertise you need to build and maintain a successful smart factory. We provide services tailored to your particular needs from a single source. Our experts are uniquely positioned to support you testing, approval and certification within any regulatory framework. We hold international accreditations recognized in every corner of the world to help you ensure your devices and machinery for smart manufacturing are effective, secure and safe.

Learn more about how you can benefit from our services!

Our experts are happy to assist you with any further questions, specific needs and requests.