Testing for Bicycles, E-Bikes, Components, and Accessories

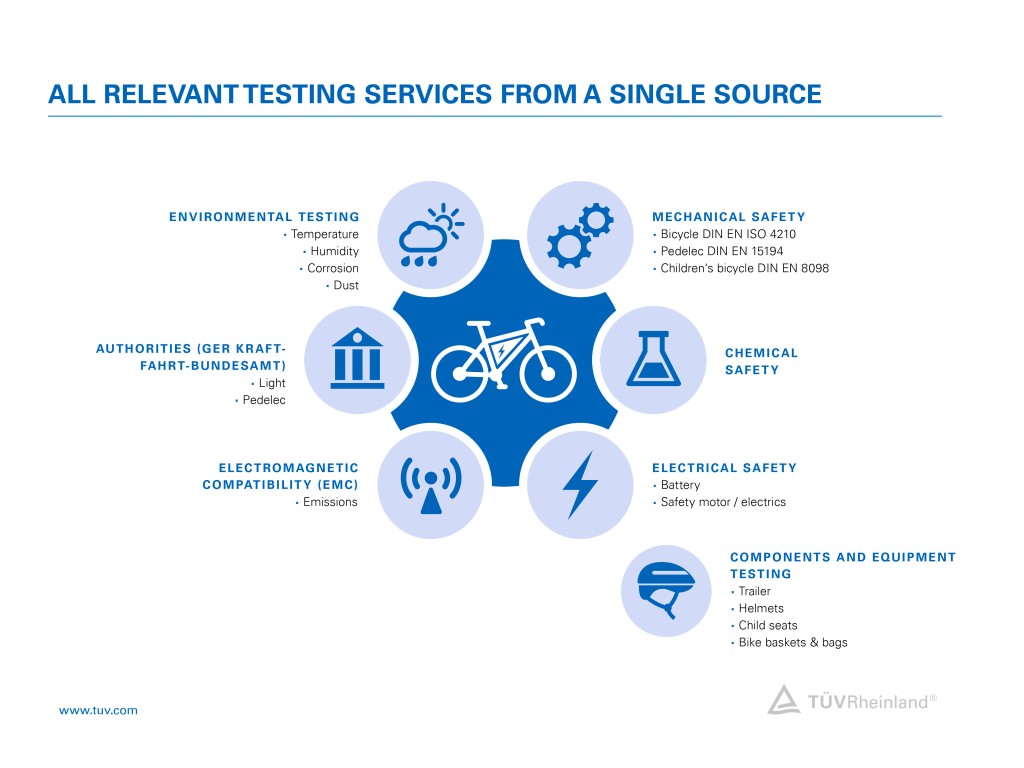

Safety Around Bicycles – All Services from a Single Source

Tested and certified quality for bicycles and e-bikes. Discover how we test products for children, bicycle helmets, and bicycle accessories in our modern laboratories – with passion for safety, innovation, and the highest standards. Our tests create trust and safety and support manufacturers in bringing their products to market successfully and in compliance with regulations.

During our video laboratory tour, you can get an impression of our modern testing procedures according to national and international standards. You can learn how complex international regulations can be in our whitepaper.

In our FAQ, we answer your most important questions and provide helpful materials for download – for a quick and transparent overview of our services.

All-in-one testing means efficient processes, fewer points of contact, and consistently high testing quality. Take advantage of the expertise and scope of a globally leading testing organization.

We also support you during the development phase or with prototypes. After successful testing, you can attach the mandatory CE or UKCA mark to your products based on our type examination certificate.

Bicycle and E-Bike Testing: Growing Safety Requirements

The bicycle market is booming – especially electric bicycles. In Germany, 86% of bicycle sales in 2024 were e-bikes. With the growing number of e-bikes, the accident rate also increases. As a manufacturer, you should leave no doubt that your product meets regulatory requirements and other quality standards.

At the same time, technical demands are rising: diverse materials, complex components, and discerning end users require manufacturers to clearly demonstrate the safety and compliance. Particularly for e-bikes, strict regulations go well beyond conventional bicycle standards.

TÜV Rheinland provides comprehensive testing expertise to support bring safe and compliant products to the road.

| Bicycles and e-bikes | |

|---|---|

| Test | Standard |

| Mechanical Safety | DIN EN ISO 4210: City bikes, trekking bikes, youth bikes, folding and racing bikes as well as mountain bikes; components such as frames, saddles, and brakes |

| DIN EN 15194: Pedelecs in the categories of city bikes, trekking bikes, youth bikes, folding and racing bikes as well as mountain bikes; components such as frames, saddles, and brakes | |

| EN 17404:2022-07: Cycles – Electrically Power Assisted Cycles – EPAC mountain bike | |

| Electrical Safety | EN 15194, EN 60335-1 and EN 60335-2-29 (charger) |

| EMC Testing | EMC Directive 2014/30/EU, DIN EN 15194 |

| Battery Testing | BATSO Standard and Low Voltage Directive 2014/35/EU |

| Chemical Analysis | PAH, plasticizers, heavy metals |

| User Manual | Testing according to ProdSG, DIN EN 82079 |

| Performance Characteristics | Fit for use (performance characteristics), durability, quality of workmanship, drum test on complete bicycle according to ISO 4210-3, Annex A |

Whitepaper – The Regulatory Landscape of the Lucrative E-Bike Sector

Interested in the booming e-bike market? On the international market for e-bikes and S-pedelecs, the latest technologies meet consumer demand. Governments have also reacted with safety regulations for pedal-assisted electric bicycles. These regulations differ significantly between countries, posing complex challenges for manufacturers and retailers. Our whitepaper helps you navigate international legislation and gain faster access to global markets.

Testing for Children’s Bicycles – Safety When It Matters

Children’s safety is our top priority. We test children’s bicycles, balance bikes, and bicycle child seats according to the latest European standards, ensuring they meet the highest levels of quality and safety.

For child seats in particular, the revised EN 14344:2022 standard introduced new requirements: material quality, protection against entrapment, prevention of strangulation hazards, and reliable adjustment mechanisms. Our testing covers all these aspects and supports manufacturers and retailers in bringing safe products successfully to market.

| Children’s bicycles | |

|---|---|

| Test | Standard |

| Mechanical Safety | DIN EN ISO 8098: Children's bikes |

| Conformity assessment for children’s bikes | Conformity assessment according to the Toy Directive 2009/48/EC |

Helmet Norm Update – Prepare

If you manufacture bicycle helmets, you are likely anticipating the updated EN 1078:2012+A1:2012. We expect the update to bring about comprehensive changes. For the first time, the new version will also take rotational forces during impact into account and introduced requirements for chin guard rigidity under specified conditions. With this update, legislators are closing an important gap: while the previous standard primarily simulated falls under standardized laboratory conditions, the new test methods will depict much more realistic scenarios in the future.

However, this means comprehensive changes to the testing procedures for bicycle helmets and helmets for other means of transport with similar risks, such as skateboard, roller skates, kick scooter and similar activities. When the standard comes into force, affected products will need to be retested, although a transition period is likely. For manufacturers, this means that the upcoming changes should be planned at an early stage so that technical adjustments can be made and retests carried out in good time.

TÜV Rheinland is ideally positioned to help. Our experts are familiar with the new requirements in detail, our testing laboratories are state-of-the-art, and our processes are designed to test your products for compliance quickly and reliably. This ensures that your helmets meet all new requirements in a timely manner – and that your products remain safe on the market.

Bicycle Components and Accessories – Safety in Detail

It is not only frames and brakes that determine safety and handling – bicycle components such as luggage racks and accessories such as bicycle bags and baskets must also be able to withstand extreme loads. At TÜV Rheinland, we test these components in accordance with current standards and realistic conditions of use.

One example is the new DIN EN ISO 11243:2024 standard, which specifies stricter testing requirements for luggage racks – especially when they are intended for use with child seats. Additional load tests are carried out here to ensure stability under shock, vibration, and unilateral load.

We also test bicycle bags under realistic conditions: We test their load-bearing capacity and secure attachment directly on the original carrier – for tested safety in everyday use.

| Bicycle accessories | |

|---|---|

| Test | Standard |

| Bicycle helmets | EN 1078 |

| Children’s bicycle seats | DIN EN 14344 |

| Bike trailers | DIN EN 15918 |

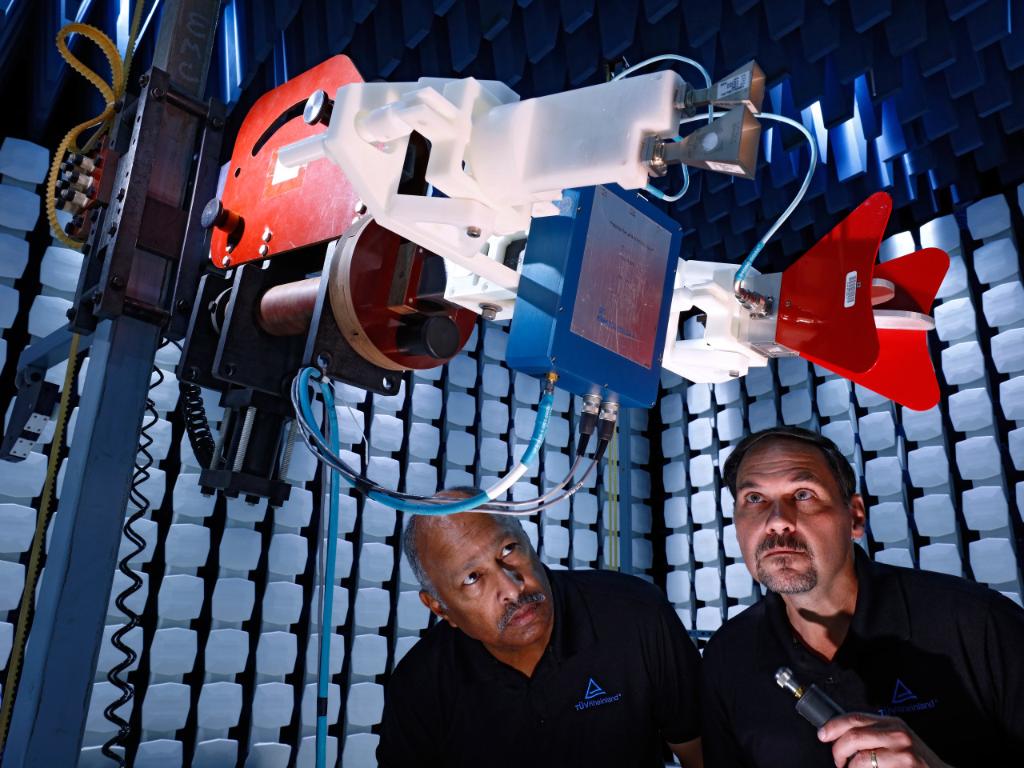

Bicycle testing at the highest level – in modern TÜV Rheinland laboratories

In our specialized bicycle laboratory, we conduct comprehensive testing of bicycles and pedelecs – from mechanical stress to EMC. Particularly important: testing batteries and power management systems under realistic conditions. Thanks to central contact persons and efficient processes, you benefit from a fast testing process without friction losses.

Our laboratories are equipped with state-of-the-art technology and also enable special tests such as range tests (R 200), power control, durability, and corrosion behavior. This not only saves you time but also costs – and ensures tested safety that creates trust.

You receive qualified test reports from a renowned independent third party. This allows you to put your bicycles and pedelecs on the road safely and increases legal certainty in liability issues.

Contact your experts for the testing of bicycles, e-bikes, components, and accessories