Welding technology

Comprehensive quality assurance in welding

Welding is a special process in which different materials are permanently joined together in order to achieve the desired properties of the end product.

Welding technology therefore plays a decisive role in various industries, such as pressure equipment construction, steel construction, construction of rail vehicles, the automotive industry and aerospace.

The welding process is complex and varies depending on the application. Special equipment and skills are therefore required, which can be learned through training, experience and expertise. Based on this, the safety and structure of the components can be guaranteed. The quality of the welded joint depends heavily on the quality assurance carried out before, during and after welding. Therefore, effective quality assurance in welding technology, such as according to the international standard ISO 3834, is crucial to ensure that the welded constructions meet the requirements for safety and reliability.

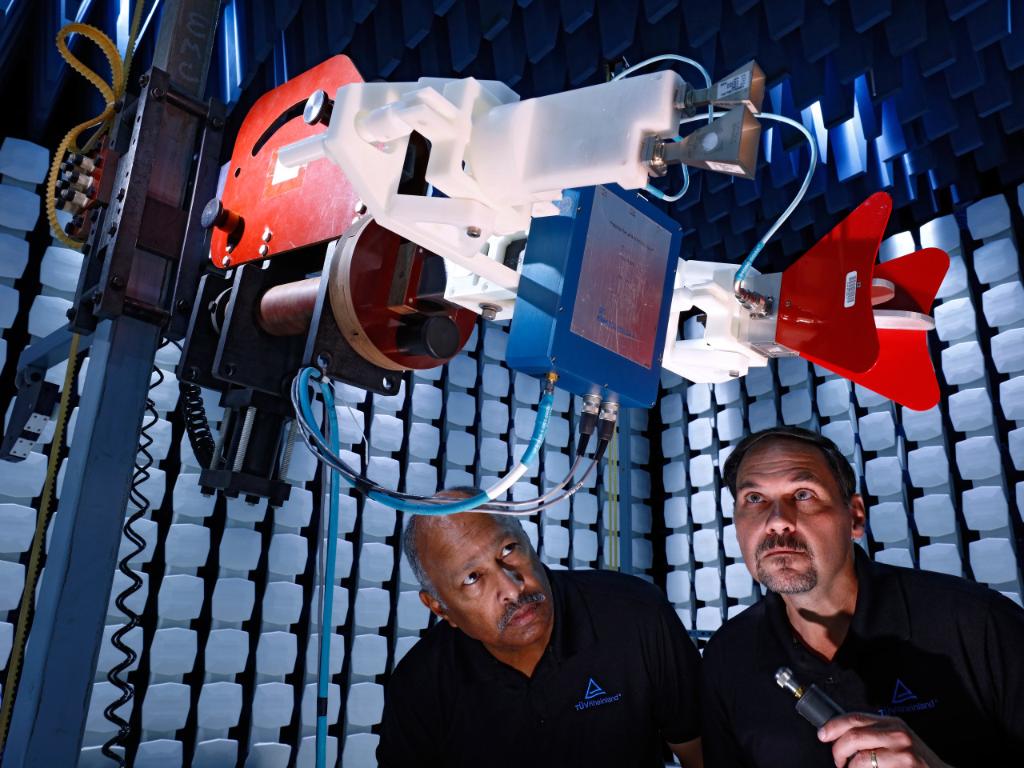

TÜV Rheinland carries out various testing and certification services in welding technology. Benefit from our many years of experience. If you have any questions or require further information, please contact us!

Your Benefits at a glance

Benefit from our many years of experience in the field of testing and certifications in welding technology by TÜV Rheinland to:

- ensure the quality of your products

- increase the competence of your employees

- comply with required guidelines and standard series, e.g. certification according to EN ISO 3834, EN 15085, EN 1090

Our welding technology certifications

Qualification of welding personnel (joining personnel)

The legal requirements and welding specifications deal with important safety aspects for the production of welded components. These include in particular the qualification of joining personnel and the welding processes used, which are defined in product standards for areas such as pressure vessel construction, steel construction, mechanical engineering and rail vehicle construction.

The specific standards specify how these qualification measures are to be carried out:

- Joining personnel, among others: EN ISO 9606 / EN ISO 14732

- Process qualification: e.g: EN ISO 15614 series

We carry out the qualification measures to ensure that the welding personnel can produce the weld seams to the required quality. If the requirements are met, a test certificate for welders and operators and a Welding Procedure Qualification Report (WPQR) are issued. These are issued as certificates within the framework of the Pressure Equipment Directive.

Regulatory context

Our experts offer you comprehensive services from a single source.

Below you will find some of the most important regulations and standards for the qualification of welding companies, joining personnel and welding procedures:

- ISO 3834: Quality requirements for welding

This certification makes it possible to demonstrate the ability of a manufacturer or fabricator to meet the quality requirements of specifications, product standards or regulations and to demonstrate compliance with European and international standards. - EN 15085: Welding of railway vehicles and components

This standard specifies the requirements for the certification and inspection of welding of rail vehicles and components. The EN 15085 is the European standard for the design, manufacture and testing of railway vehicles and equipment. - DIN 2303: Quality requirements for production and maintenance companies for military products

This standard specifies the requirements for quality assurance systems and describes the procedure for obtaining the manufacturer qualification for welding of defence technology products. - EN ISO 17660: Welding - Welding of reinforcing steel

This standard specifies the requirements for manufacturer and process qualifications of welding of reinforcing steel. - EN ISO 9606: Qualification testing of welders

This standard specifies the requirements for testing the manual skill of welders of metallic materials. - EN ISO 14732: Welding personnel - Approval of welding operators

This standard specifies the requirements for the testing of operators and setters for mechanical and automatic welding of metallic materials.

Contact