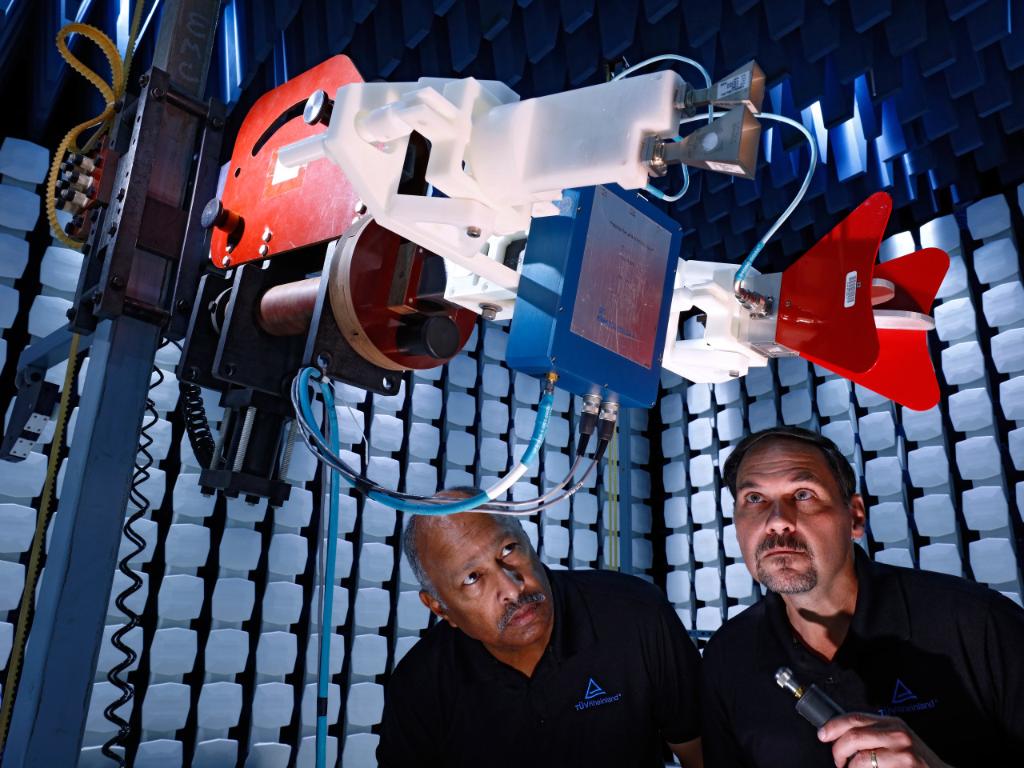

EN 15085-2 - Welding of Railway Vehicles

Compliance with EN 15085-2 for the highest quality standards in the rail market

Do you manufacture, repair, design, assemble, purchase or sell rail vehicles or their components? Then certification to EN 15085-2 is the basis for this. We at TÜV Rheinland are an accredited manufacturer certification body and are recognized by the European Council for Welding of Railway Vehicles (ECWRV) to list you as a manufacturer in the ECWRV's proven online register. With this certification, you can access to the international rail vehicle construction market.

Benefit from our many years of experience. If you have any questions or require further information, please contact us at !

EN 15085-2: Levels of quality requirements

The standard defines three classification levels (CL) depending on the safety relevance, which describes the consequences of the failure of a welded component with regard to the effects on persons, equipment and the environment:

- CL1 - For welded rail vehicles and their components with high safety relevance.

- CL2 - For welded attachments of rail vehicles with medium safety relevance.

- CL3 - For simple welded attachments of rail vehicles with low safety relevance.

The classification levels are assigned to the corresponding fields of activity, such as design, production, maintenance, purchasing and delivery.

The EN 15085-2 certification process

- Application

If all requirements are met, the manufacturer can apply for certification in accordance with EN 15085-2. - Initial inspection

TÜV Rheinland coordinates the entire certification process and carries out the initial inspection. - Certificate

If you meet all the necessary criteria, as a manufacturer you will receive the certificate - Welding of rail vehicles and vehicle parts according to EN 15085-2. With the certificate according to EN 15085-2, you not only prove the qualification of your employees and the necessary technical equipment, but also compliance with the normative requirements of your welded products.

As a tested and certified manufacturer, you will be listed by us in the registered in the online register https://en15085.joincert.e u and Certipedia.

You will receive a TÜV test mark on request. - Regular inspection

TÜV Rheinland monitors compliance with EN 15085-2 at regular intervals. The inspection focuses on the personnel requirements for welding supervisors, welding and testing personnel, operational facilities and equipment, process qualifications and planning documents as well as the quality assurance system.

Your benefits at a glance

With certification to EN 15085-2 from the experts at TÜV Rheinland:

- you fulfill the welding requirements of the standard in rail vehicle construction

- gain access to the international market for rail vehicles and rail vehicle components.

- benefit from the many years of experience of our experts.

Our welding technology portfolio

Contact