In what way do these new products and applications change or expand the testing requirements?

Gerhard Richter: As enjoyable as the electrical and digital enhancement of the bathroom experience may be, bathrooms will always involve water, which is of course not compatible with electricity. There will always be splashing water in a bathroom, which is why the ISO 20653/DIN EN 60529 requirements with protection ratings such as IP 44 play a key role in our product testing. It also includes high-voltage testing, for example for the housing and the electrical components of mirror cabinets.

Electrical safety must always be ensured, including for those newer electrical features. And we don't simply test at 230 volts, but at up to 1.5 times the mains voltage. Because no matter how much the voltage may fluctuate, the shower water must never exceed 40 degrees Celsius, the toilet seat heating must never cause burns, and the toilet's bidet shower must never be outside the specified temperature range. In addition, there are special requirements for whirlpool baths and for lighting and entertainment technology.

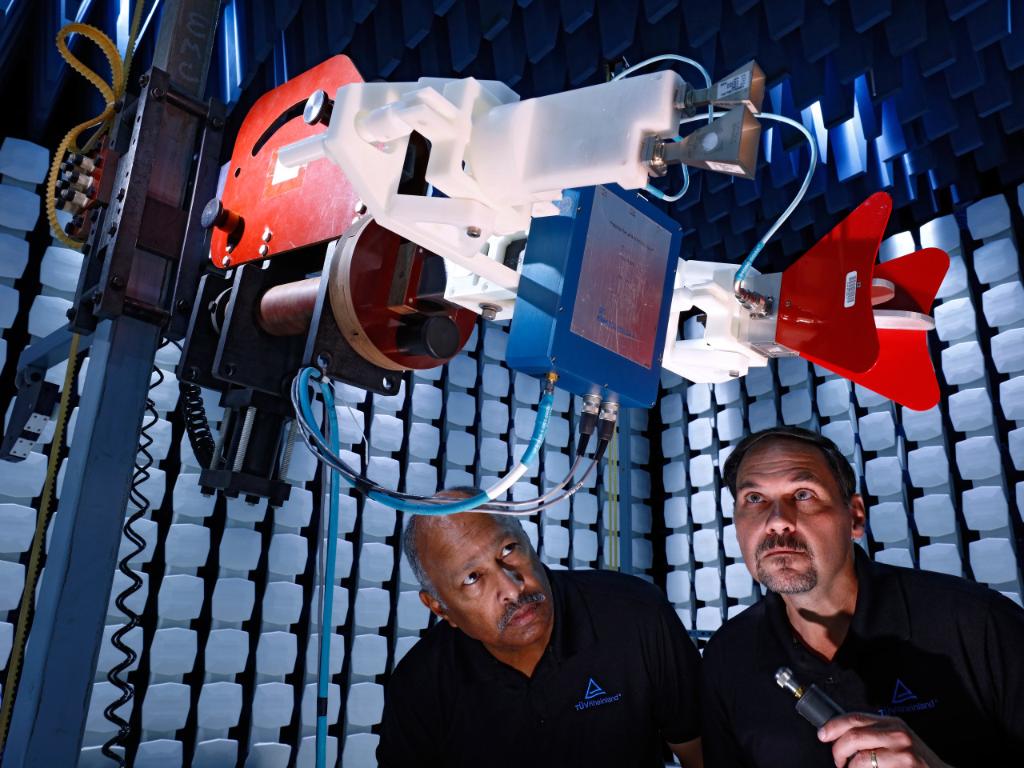

For digital installations, there are additional aspects that are still somewhat unusual for bathrooms – e.g. EMC testing for electromagnetic compatibility, wireless testing, or cybersecurity tests. Another key standard is DIN/EN 15091, which specifies the requirements for labeling, identification, leak-tightness, electrical safety, operational safety, functionality, and mechanical resistance of sanitary taps that have an electronic opening and closing function.

![]()

“For digital installations, there are additional aspects that are still somewhat unusual for bathrooms, e.g. EMC testing, wireless testing, or cyber-security tests.”

Gerhard Richter

What happens if manufacturers do not meet these standards?

Gerhard Richter: Most of these tests are mandatory. This means that if a product does not comply with the regulatory requirements, the manufacturer cannot place it on the market here. However, we also offer a wide range of optional tests, which are increasingly requested by big manufacturers to give their products a unique selling point or a test mark for promoting sales.

What are the benefits of optional product testing for manufacturers?

Gerhard Richter: Our optional tests are very much in demand. Manufacturers often intentionally choose risk-oriented tests. At TÜV Rheinland, we then do not act as a Notified Body, but prepare individual test reports. One example: There is no requirement to test the photobiological safety of cool white LED lights, but for some manufacturers, it is very important. The same is true for the level of noise produced by bathroom fixtures that can be heard in adjacent rooms. Anyone who has ever been woken up by a late-night shower in an apartment building or hotel knows what we are talking about ...

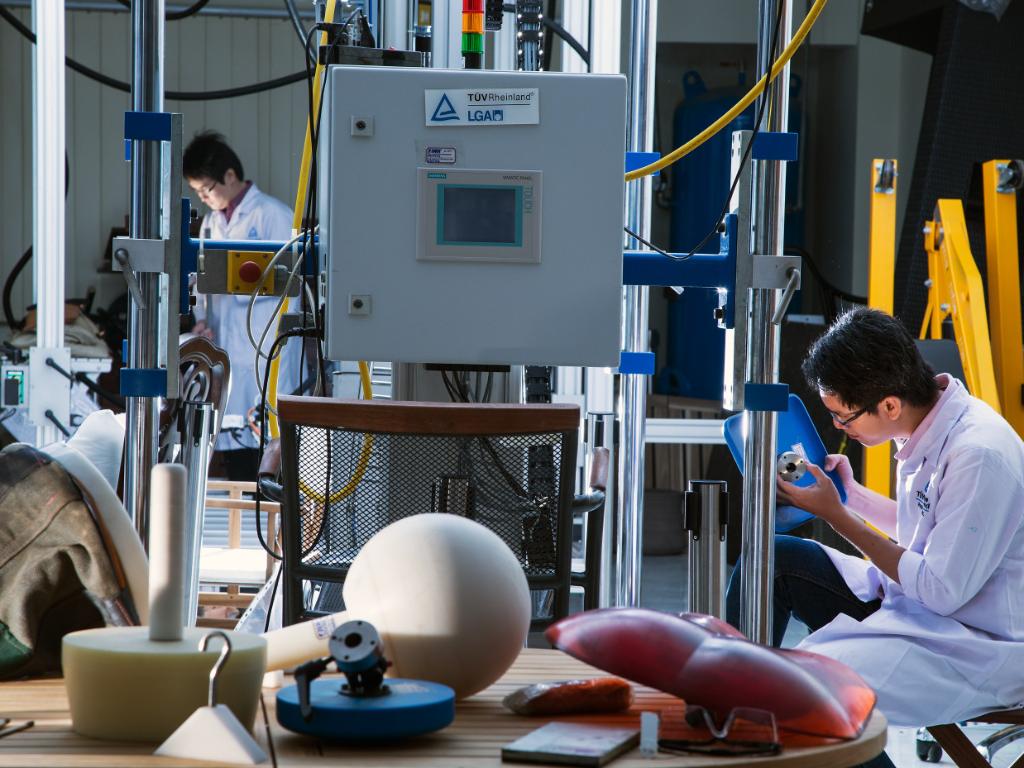

Of course, we also offer the GS certification mark. However, “GS” only applies to finished products – so it is not an option for permanent installations. The “Bauartgeprüft” (type-tested) test mark is an attractive option for many manufacturers. For this test mark, we create an individual test plan and conduct electrical, mechanical, and chemical tests. It also includes a manufacturing inspection. As part of this inspection, we assess for example, whether the workforce has been properly trained and whether the installed components conform to the documentation. Manufacturers recognize the significant added value of these optional tests, such as being able to use the “Bauartgeprüft” test mark in many different EU countries.

When should manufacturers have their products and applications tested?

Martin Fries: It makes perfect sense and is common practice not to wait for the finished product to do those tests, but to have prototypes tested at various stages of development. In this phase, manufacturers also consult us to understand certain standards and guidelines. In technical consultations, we then discuss any potential normative weaknesses or challenges for each individual product.

Is it your experience that manufacturers are familiar with the (changing) regulatory requirements?

Gerhard Richter: The big players in the industry know the requirements and even employ their own electrical engineers and electronics technicians to ensure that their products are compliant from the very beginning. However, even these companies still like to consult us during product development – for example with questions about how to interpret a particular standard. There are currently many new guidelines and standards being released, which presents manufacturers with major challenges.

The situation may look different for importers of low-price products: Sometimes they buy a product and only find out after our tests that a label or a warning is incorrect or that a component or even the entire product does not comply with the Certificate of Conformity. This is very upsetting of course. It would be better to involve us at an early stage, once they have a test sample, and potentially have us carry out an assessment.

Gerhard Richter

Gerhard Richter

Martin Fries

Martin Fries