Materials and components used in the hydrogen economy must be able to withstand very specific challenging conditions. Atomic hydrogen can penetrate materials, cause hydrogen embrittlement and damage them to the point of component failure.

Our TÜV Rheinland H2.23 certification standard combines the state of the art with our global expertise in hydrogen suitability, and certifies that materials used in critical applications such as pipelines and pressure vessels in large industrial plants are suitable for use with pressurized hydrogen.

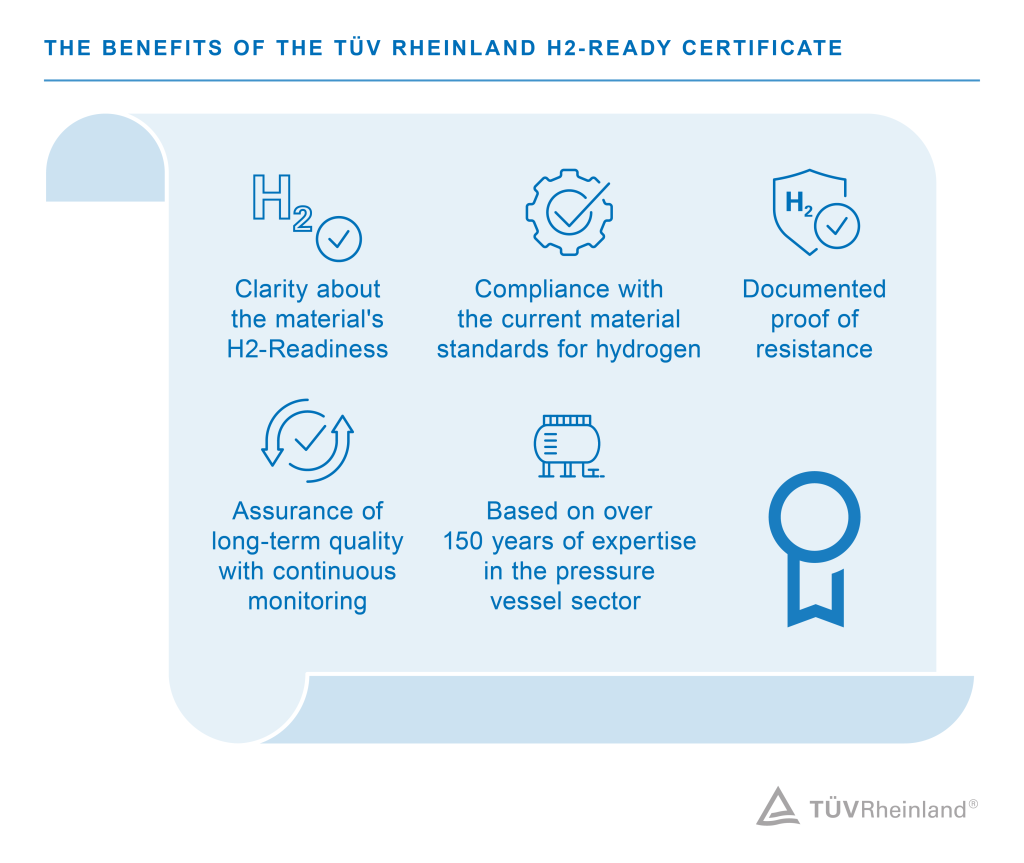

The benefits of the TÜV Rheinland H2-Ready Certificate

- Representation of the state of the art regarding resistance to pressurized hydrogen

- Qualification of metallic materials according to the TÜV Rheinland H2.23 certification standard

- Consideration of the intended use of the material

- Testing in a pressurized hydrogen atmosphere

- "H2-Ready" certificate and distinguished test mark

H2.23 certification standard in two steps

Questions? We have the answers!

Would you like to learn more about the certification of materials and components? We answer the main questions.

Show all

Hide all