TÜV Rheinland Automotive Component Testing GmbH offers you services for validation and type testing along the value chain of the development of vehicle battery systems up to 800 kilograms. Based in the Dutch-German industry park Avantis in Heerlen-Aachen we use a battery test laboratory with a size of approx. 2,000 square meters. This laboratory is an essential part of a technology hub. Several mobility startups as well as companies of the mobility industry are also located there.

About TÜV Rheinland Automotive Component Testing GmbH

TÜV Rheinland Automotive Component Testing (ACT) GmbH is a joint venture of TÜV Rheinland Kraftfahrt GmbH and ConAC, part of the PEM Network, founded in 2020. PEM is an engineering service provider offering solutions for future mobility topics. TÜV Rheinland ACT is part of the Future Mobility Hub Avantis. We already offer a wide range of battery tests for our customers. Starting from performance tests, over mechanical tests up to abuse tests.

New test laboratory for traction batteries

We are testing all types of batteries

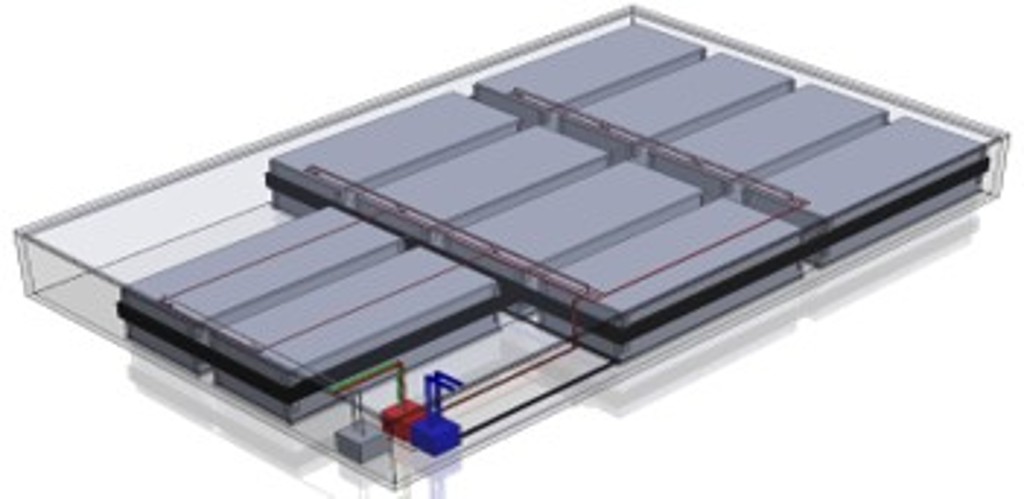

Type of battery: Testing services primarily for battery packs and modules

Dimension, weight and power: Your test specimen can have a mass up to 800kg and 150kWh with a size of 2,3m x 1,6m x 0,4m (D x W x H ). Customized parameters on request.

Sample testing: We can perform battery testing from prototype to D sample

Impressions of the laboratory

Battery standards

Battery services that we already offer today

- Testing services

- Testing equipment

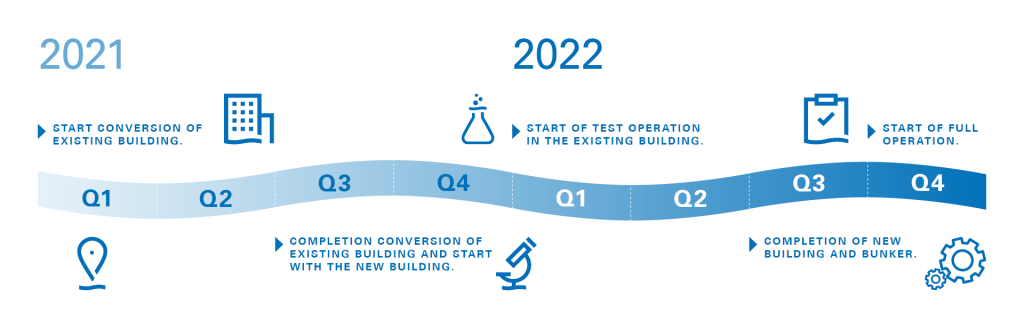

Roadmap till end of 2022

Work in progress

Interested in our battery testing services?