70 years of commitment to safety: TÜV Rheinland celebrates seven decades of toy testing

Cologne | 05 June, 2025

On the International Day of Play on June 11, TÜV Rheinland looks back on 70 years of toy testing. Since 1955, experts have been working to ensure that toys are safe and harmless for children. What once began with simple mechanical tests has evolved into a complex testing process based on international standards. The goal has remained the same for 70 years: to ensure the best possible protection for children at play.

Playing – and testing – with all senses

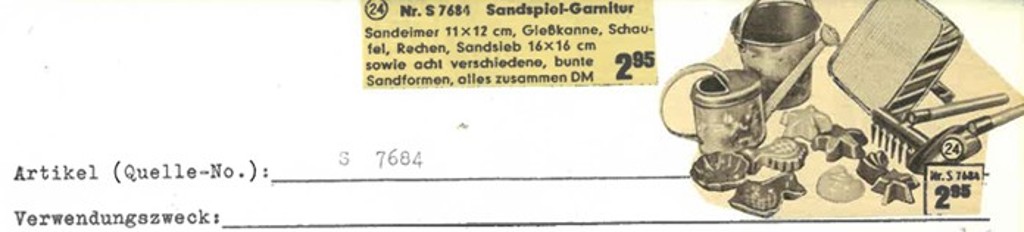

TÜV Rheinland’s employs approximately 500 toy testers worldwide, who examine tens of thousands of toys each year. “How does the toy smell, how does it feel, how loud is it - all this gives us information about its safety and quality,” says Sebastian Rösch, Laboratory Manager of TÜV Rheinland's Nuremberg toy testing lab where it all started. This was already the case with the first test object, a sand play set, tested back in 1955 by TÜV Rheinland, which was then still known as the Landesgewerbeanstalt Bayern (LGA). Today, video drones and interactive robots with intelligent speech recognition are arriving at the test laboratory in Nuremberg, the largest of its kind in Europe. Data protection and cybersecurity are playing an increasingly significant role here.

Toy developments influence standards

In the 1950s, consumer tests already common in the USA sparked demand in the expanding Western European markets for qualified, neutral product evaluations. In the absence of established standards, practical experience had to be relied upon. The basis for testing comprised adapted product tests and standards, such as those from the field of industrial equipment inspection.

As the use of noise-generating electronic components soon became economically attractive and began influencing toy design, standardization bodies had to respond accordingly. They established and continually refined limits for noise-generating toys.

In the 1970s, systematic testing procedures for physical and mechanical properties were introduced, along with the first standards (DIN 66070-1/-2). The 1980s brought new standards for electric toys with DIN 57700-210, while in the 1990s, the focus was on chemical safety and the harmonization of European standards. In the 2000s, TÜV Rheinland responded to the increasing prevalence of electronic and battery-operated toys with adapted testing methods - including safety assessments for swallowable magnets, which were regulated in EN 71-1 in 2009.

Current focus: Cybersecurity and chemical testing

Topics such as artificial intelligence and cybersecurity are now also dominating toys. Smart toys are connected to the internet and could potentially be gateways for cyber criminals. The EU has already responded by developing corresponding regulations. On August 1, 2025, new security requirements under the Radio Equipment Directive (RED) will come into effect, applicable to all internet-enabled products. These regulations aim to significantly enhance the protection level of such devices.

In recent years, per- and polyfluoroalkyl substances (PFAS), known as “forever chemicals”, have garnered increased attention. The industry uses PFAS to make surfaces dirt-repellent, waterproof or grease-repellent, for instance in plush toys, making them easier to clean. PFAS degrade very slowly and are suspected of being harmful to the environment and health. With a digital product passport for toys and the toy safety regulations adopted in April 2025, the EU wants to ensure compliance with these requirements. TÜV Rheinland offers companies the opportunity to safeguard their products and supply chains accordingly, promoting a more environmentally friendly and sustainable production.

CE, GS mark and “Excellent Play Value”

The CE mark (conformité européenne) is mandatory for all products sold within the EU. With the CE mark, a manufacturer declares that their product meets all EU-wide requirements for safety, health protection and environmental protection.Those seeking higher standards than the legal minimum - particularly in chemical testing - can look for the "Tested Safety" (GS) mark or TÜV Rheinland's "Toyproof" seal. The “Excellent Play Value” certification from TÜV Rheinland shows the extent to which a toy promotes a child's development in educational and psychological terms. Recognized experts assess educational and developmental aspects, for example.

About TÜV Rheinland Toy Testing

For over 70 years, TÜV Rheinland has been supporting the toy industry and employs about 500 experts dedicated to toy testing worldwide. Every year, these specialists test more than 40,000 toys globally across various categories, including mechanical properties, flammability, sound levels, plasticizers and electromagnetic compatibility. They test all toys intended for children up to the age of 14. The experts develop new testing methods, inspect production facilities and work on research and development initiatives as well as in standardization committees. They conduct feasibility studies during the production phase, identify potential hazards and facilitate global market access. As a leading testing service provider, TÜV Rheinland operates laboratories in Nuremberg, Hong Kong, Shanghai and Bentonville, among others. Information at: www.tuv.com/toy-testing

| docx | press release (.docx) | 213 KB | Download |

| jpg | press photo 1 | 1 MB | Download |

| jpg | press photo 2 | 1 MB | Download |

Your contact for editorial inquiries:

TÜV Rheinland Press Office

Do you have any questions on this topic or need further information?

Please do not hesitate to contact us:

Phone: +49 221 806-2148