ISO 10218-x:2025 - New benchmarks for safety in robotics

The International Organization for Standardization (ISO) recently published the revised versions of the standards ISO 10218-1:2025 Industrial robots and ISO 10218-2:2025 Robot systems, robot applications and integration. This update was urgently needed - not only because the previous versions dated back to 2011, but above all because the possible applications and technical complexity of industrial robotics have developed rapidly in recent years.

With the updated standard, ISO is taking account of the requirements of modern robot production and at the same time creating a globally uniform foundation for greater safety, efficiency and sustainability - both for manufacturers of robots and robot cells and for their operators.

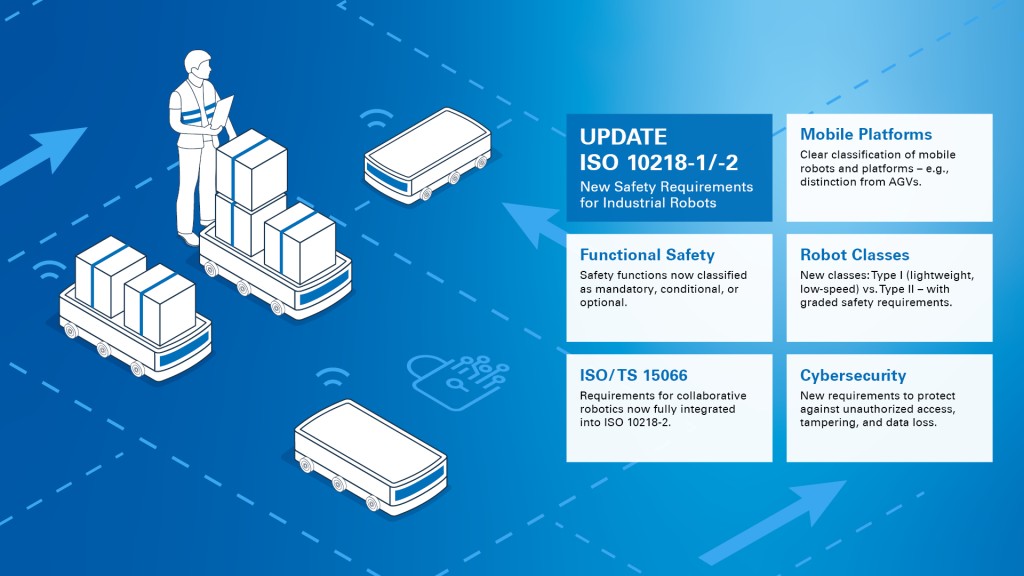

What's new? - An overview of the most important changes

- Mobile platforms clearly defined for the first time

A key advance is the formal definition of the term “mobile platform”. This paves the way for mobile robots to be assessed more precisely and classified correctly in terms of safety. The same assessment standards now apply to mobile platforms as to automated guided vehicles (AGVs). This provides clarity - especially for manufacturers who develop hybrid or modular robot systems. - Functional safety: clear specifications on performance levels

The requirements for functional safety have been comprehensively revised. All relevant safety functions are listed in the newly structured Appendix C - each with a classification as to whether they are mandatory, conditionally required or optional. In addition, each of these safety functions is assigned a specific performance level (PL) in accordance with EN ISO 13849. This provides manufacturers and system integrators with concrete specifications for technical implementation. - Introduction of robot classes

Another important innovation is the classification of robots into two groups: Class I comprises light, slow robots with limited performance to which reduced safety requirements apply. Class II includes all other industrial robots. This distinction makes it possible to design safety measures that are more targeted and proportional to the risk potential - an advantage for manufacturers who develop lower-performance collaborative robots. - Integration of ISO/TS 15066 into ISO 10218

The requirements for collaborative operation have been fully incorporated into ISO 10218-2. This eliminates the need to consider ISO/TS 15066 separately as an independent specification - even if it remains valid, for example as a reference in other standards. This standardization ensures greater clarity and less effort in the normative assessment of collaborative robotics applications. - New cybersecurity requirements

In view of the millions of networked industrial robots worldwide, it was only a matter of time before the standard also included cybersecurity requirements. The updated ISO 10218 now explicitly requires measures to protect against unauthorized access, manipulation and data loss - an important step towards securing industrial systems against digital threats in the future.

Why the new standards are so important now

The revised ISO 10218 not only takes account of technological developments - it also creates legal certainty. In many international markets, ISO standards are regarded as the binding state of the art. Anyone who develops or sells robots and robot cells should therefore ensure that their products meet the new requirements.

Operators of robot systems are also affected: they have a legal duty of care and must ensure that the systems used comply with the latest safety standards - especially when integrating new components or software updates.

"ISO 10218:2025 is not a simple update - it marks a fundamental reorientation of safety in industrial robotics. Those who deal with the new requirements at an early stage will not only gain a technical advantage, but also an economic one," explains Sergey Logachev, expert for automation, robotics and functional safety at TÜV Rheinland.

Our experts have already dealt intensively with the updated standards. We support manufacturers and integrators with practical implementation - from the evaluation of existing systems to the development of new, standard-compliant robotics solutions.

Conclusion: More clarity, more responsibility - and new opportunities

With the revised ISO 10218-1:2025 (Safety requirements for industrial robots) and ISO 10218-2:2025 (Safety requirements for robotic systems, applications and integration), ISO is creating a modern and binding framework for the safe development and use of industrial robotic systems. The extended requirements provide greater clarity and promote a common understanding of safety at an international level.

At the same time, responsibility is increasing: manufacturers are required to implement safety functions in a more targeted manner and to integrate new aspects such as cyber security into their development processes at an early stage. Operators also need to be aware of the changed requirements in order to fulfill their duty of care - especially when selecting, integrating and operating robot systems.

Despite the additional effort involved, the new standards also open up clear opportunities: those who respond to the new requirements at an early stage not only reduce risks, but also increase market acceptance and future-proof their products.

Would you like to check the extent to which your current products or processes comply with ISO 10218-x:2025 - or do you need support with standard-compliant development?

Our experts will support you with in-depth expertise and practical solutions - from the initial assessment to the actual implementation. Get in touch with us. Together we will design the safe robotics of tomorrow.