Personal Care Robots

Personal Care Robots

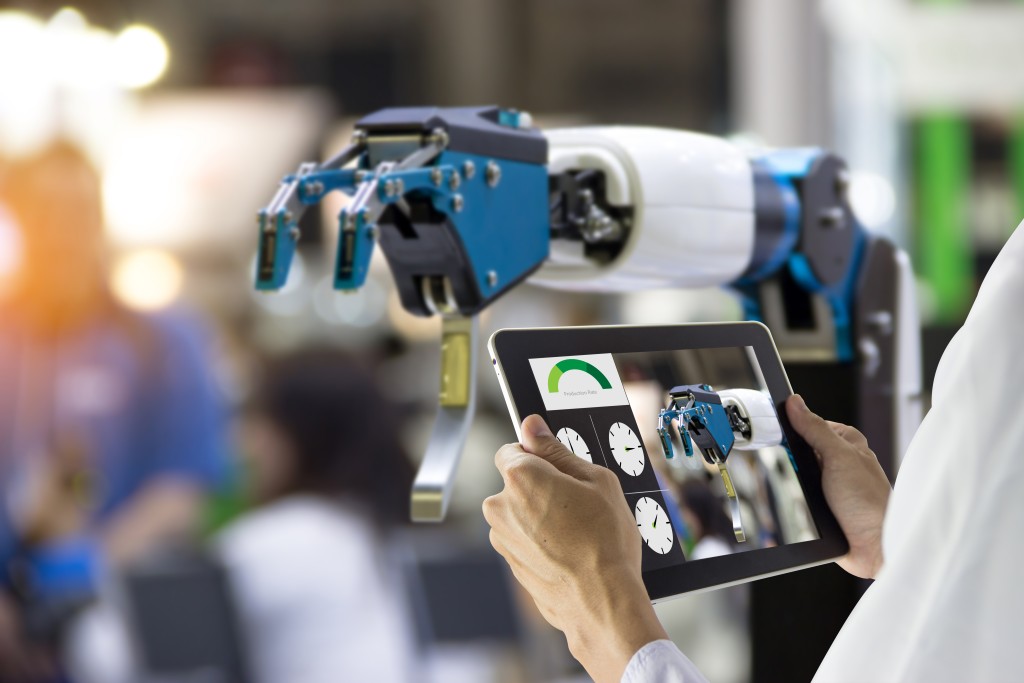

Industrial Robots and Cells

Industrial Robots and Cells

Personal care robots perform actions that improve the quality of life for humans (excluding medical applications). Mobile servant robots are capable of traveling to perform their tasks, such as handling objects or exchanging information. Because they’re intended for non-industrial areas, they’ll be used by untrained people, so safety concerns are paramount.

Common Standards

- ISO 13482

- Machinery and EMC Directives

- IEC 60204-1

- UL 3300

Services and Solutions

- cTUVus mark

- Functional safety review and certification

- Test reports, T-Marks, other international certification to ISO 13482 and IEC/EN 60204-1 as needed

- CE Marking Assistance

The traditional industrial robot is an actuated mechanism programmable in two or more axes. It has a degree of autonomy, moving within its environment to perform intended tasks. The robot includes the control system and that system’s interface. A robot cell is a complete system, including the robot, controller and other parts needed to allow the robot to function safely in the work environment, such as guards and conveyors.

Common Standards

- ANSI/RIA R15.06 Part 1

- ANSI/RIA R15.06 Part 2

- CAN/CSA Z434 Part 1

- CAN/CSA Z434 Part 2

- UL 1740

- ISO 10218-1:2011 and !NEW! EN ISO 10218-1:2025

- ISO 10218-2:2011 and !NEW! EN ISO 10218-1:2025

- Machinery and EMC Directives / Machinery Regulation (EU) 2023/1230

Services and Solutions

- cTUVus mark

- Functional safety review and certification

- Field evaluation

- Test reports, certifications, other international certification to ISO 10218-1 and/or ISO 10218-2 for the robot itself or robotic cell

- CE Marking Assistance

Autonomous Mobile Robots

Autonomous Mobile Robots

Collaborative Robots

Collaborative Robots

An AMR is a multi-axis system that can independently choose a path based on its environment (as opposed to a predefined path). The robot may also be integrated with an automated attachment. Unlike personal care/mobile servant robots, these robots are intended for industrial use.

Common Standards

- ANSI/RIA R15.08

- CAN/CSA Z434

- UL 3100

- ISO 10218-1

- Machinery and EMC Directives / Machinery Regulation (EU) 2023/1230

Services and Solutions

- cTUVus mark

- Functional safety review and certification

- Field evaluation

- Test reports, T-Marks, other international certification as needed

A collaborative robot is designed for direct interaction with a human in a defined collaborative workspace. Specifically, such a workspace is defined as the area in which a robot and human can perform tasks concurrently during a production operation. (These are defined in ANSI/RIA R15.06 and ISO/TS 15066/ EN ISO 10218-2.) Collaborative robots are one of the hottest areas in the robotics field, projected to grow more than 50% annually.

Common Standards:

- ANSI/RIA R15.06

- RIA/TR R15.606

- RIA/TR R15.806

- UL 1740

- CAN/CSA Z434

- ISO 10218-1:2011 and !NEW! EN ISO 10218-1:2025

- ISO 10218-2:2011 and !NEW! EN ISO 10218-2:2025

- ISO/TS 15066 (Requirements transferred to EN ISO 10218-2)

- Machinery and EMC Directives / Machinery Regulation (EU) 2023/1230

Services and Solutions

- Test reports and potential certification in accordance with ANSI/RIA R15.06

- Test reports and certification to UL 1740

- Test reports and potential certification in accordance with CAN/CSA Z434

- Evaluation of collaborative robot cells in accordance with RIA/TR R15.806 and RIA/TR R15.606

- Test reports for robot cells in accordance with EN ISO 10218-2

- Test reports for collaborative robot cells in accordance with ISO/TS 15066 or EN ISO 10218-2:2025

- CE Marking Assistance

Automated Guided Vehicles

Automated Guided Vehicles

In North America, a distinction is made between mobile robots and automated guided vehicles (AGVs). An AGV is a battery-powered industrial transporter or service vehicle that is operated autonomously - i.e. without a driver. AGVs have a lower level of autonomy than mobile robots. They navigate on predefined routes and cannot vary these independently. These vehicles are most commonly used in warehouses and factories to transport materials. These vehicles are most frequently used in warehouses and factories to transport materials.

Common Standards

- UL 583

- ANSI/ITSDF B56.1

- ANSI/ITSDF B56.5

- ANSI/NFPA 505

- EN 1175-1

- EN ISO 3691-4

- Machinery and EMC Directives

Services and Solutions

- cTUVus mark

- Functional safety review and certification

- Field evaluation

- Test reports, certifications, other international certification as needed to ISO 3691-4, EN 1175-1

- CE Marking Assistance